Calculating costs...one moment...

Material:

Total cost (shipping included) :

If you have previously ordered from us, enter email only; we will use your address on file.

When purchasing a mold, you have to make two decisions: 1.) What kind of mold do you want, and 2.) Do you need us to add

a sprue and riser?

1.) What kind of mold do you want There are currently three types of mold available. The first is an open faced, single piece mold.

One side of the mold is open, and you simply pour in the resin. This is perfect if have an object with details on one side and the other

side is flat.

The second mold type is a planar two-piece mold. This is a two piece mold that will split along the z=0 (a.k.a. x-y) plane of your STL.

Because it is a two piece mold you can have details on both sides.

Submit your STL with the plane z = 0 as the parting line-we don't adjust your STL for you!

The third mold type is a contoured two-piece mold. This is also a two piece mold but the split does not need to follow a single plane.

This type is ideal for shapes that require complex surfaces that are not all in one plane. For example, a spoon or a bowl would require this

type of mold, a z plane mold would not follow the contours correctly.

It is important to note that this type of mold requires a single contour that is the outermost edge of the object. Of note, objects with flat

vertical surfaces are not suitable because the 'outermost edge' is ambiguous and could be at the top or bottom of the face. In this case

adding a small draft to the object will resolve the problem.

For a video on the different mold types,

click here.

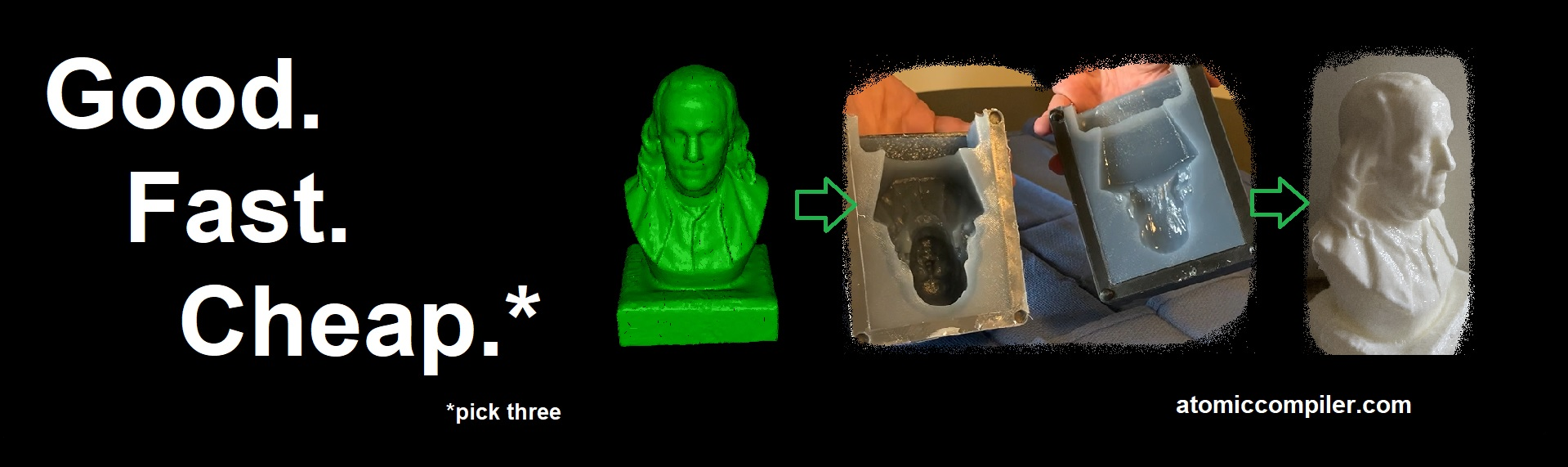

Here are three pictures of the different types of molds, open faced, two piece planar, and two piece contoured, respectively.

2.) Do you need us to add a sprue and riser? For the two piece molds, you need at minimum a sprue to pour in the resin, and a

riser to allow air to excape during the pour is strongly recommended. WE STRONGLY RECOMMEND THAT YOU PLACE YOUR OWN SPRUES AND RISERS

The positive y direction is the 'top' of the mold and the sprue should be oriented in that direction.

If you do not want to add these yourself, we can add a filling sprue at the lowest point and a vent at the highest point, however

be aware that we cannot guarantee these will work for your application as we don't know the pouring characteristics of your resin. Also,

be aware that the sprues and risers will increase the size of your STL and significantly increase your mold cost.

Molds can be lined with silicone, flexible urethane, and plaster. The correct choice depends

on the application.

Silicone is a durable, flexible, chemical and temperature resistant material that is ideal for making molds

for plastic resins such as epoxies and urethanes. Straight vertical edges or even mild undercuts are acceptable,

although there may be a decrease in the lifespan of the mold. Silicone can also be used to cast hot was for

lost wax casting applications. We use food-safe platinum cure silicone, so the molds can also be used for food products.

Urethane is also soft and flexible, and should be used instead of silicone for casting cements and plasters. Properties

are similar to silicone; mild undercuts are acceptable.

Plaster is a rigid liner which should be used for slip casting of ceramics. Because plaster is rigid undercuts are not acceptable,

even vertical surfaces will generally cause problems. Molds should have a draft of several degrees to avoid castings sticking in the mold.

Click here to view a video on mold types.

Thank you for your order! Our staff will review the file to make sure there aren't any issues and will reach out

via email if necessary. In one to two business days, after the file is reviewed, you will receive

an email invoice that you can pay via paper check,

e-check (ACH), credit card, or paypal.

If you have any questions you can email sales at atomiccompiler dot com directly.